SUBCOMPONENT TABLES

Built to Last

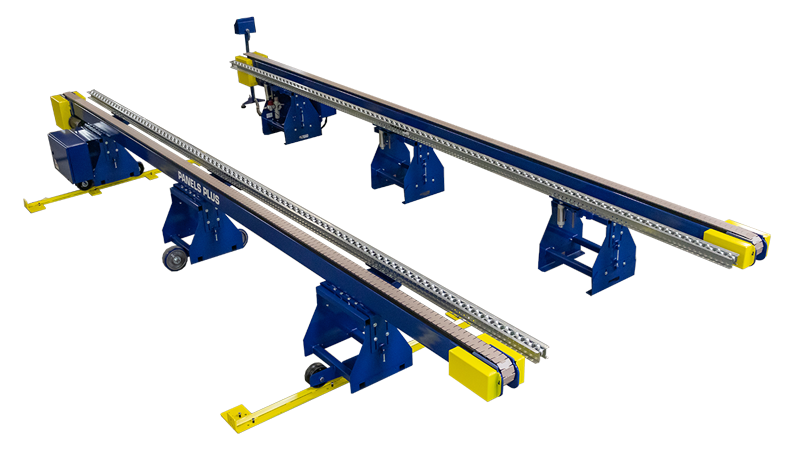

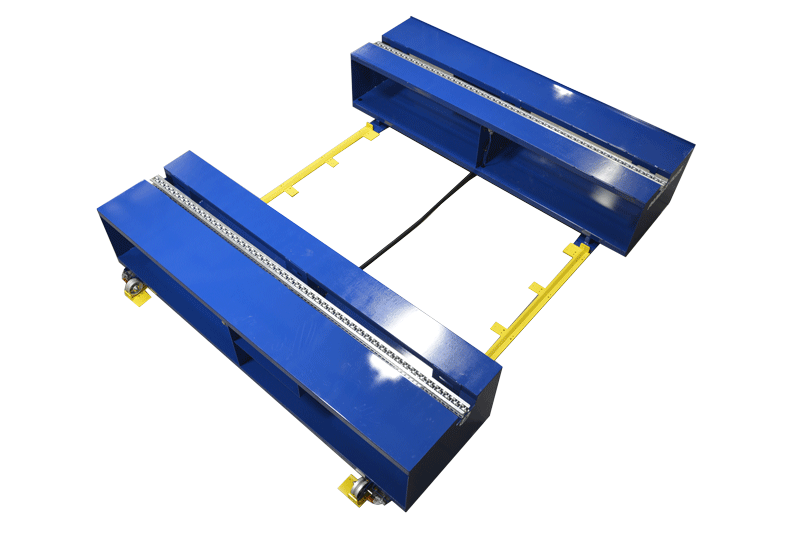

The Panels Plus Subcomponent Tables are designed for building rough opening sections. They feature pop-up rollers, a squaring edge, and a manual telescoping side to easily adjust and set the wall height. The pop-up rollers make it easy to move product down the production line.

Benefits

- Ease of moving product down the production line via pop-up rollers

- More than 1 person can work at a station

- Ergonomic working height

Subcomponent Tables

The Panels Plus Subcomponent Tables are designed for building rough opening sections. They feature pop-up rollers, a squaring edge, and a manual telescoping side to easily adjust and set the wall height.

The pop-up rollers on the Subcomponent Tables make it easy to transition subcomponents from the tables to your desired location or down the production line. They are developed at an ergonomic working height, eliminating the need to continually kneel or hunch over to build subcomponents.

The Subcomponent Tables are available in two different versions, a 12’ and 18’. The 18’ table can also be used for hand framing interior lines in addition to building rough openings.

Subcomponent Tables Specs

| Electrical | • N/A |

| Air | • 5 CFM @ 90-120psig |

| Table Height | • 33’’ |

| Table Length | • 12’ or 18’ |

| Minimum Table width | • 84’’ |

| Maximum Table Width | • 14’ 5’’ |

| Manually Telescoping Side | • Adjusted in and out to set the panel height |

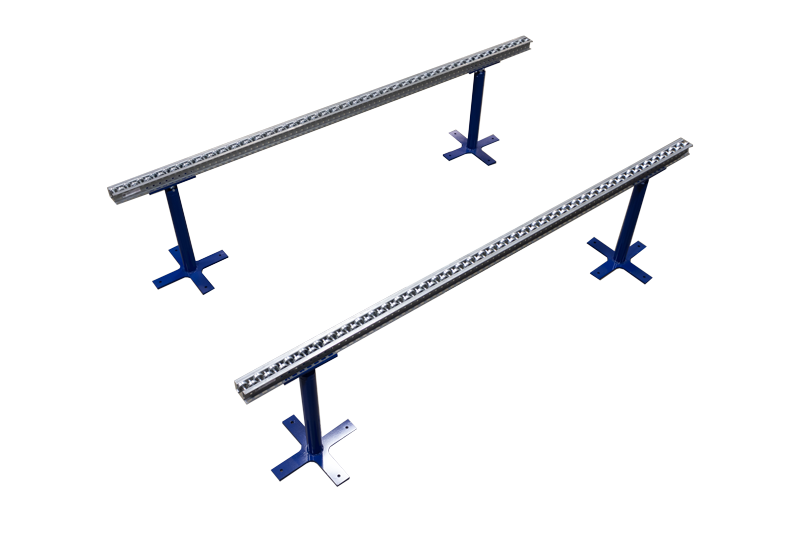

| Pop-Up Rollers | • Raised by push-button controls • Allow easy panel movement down the production line |

| Squaring Edge | • Ensures squareness of subcomponents |