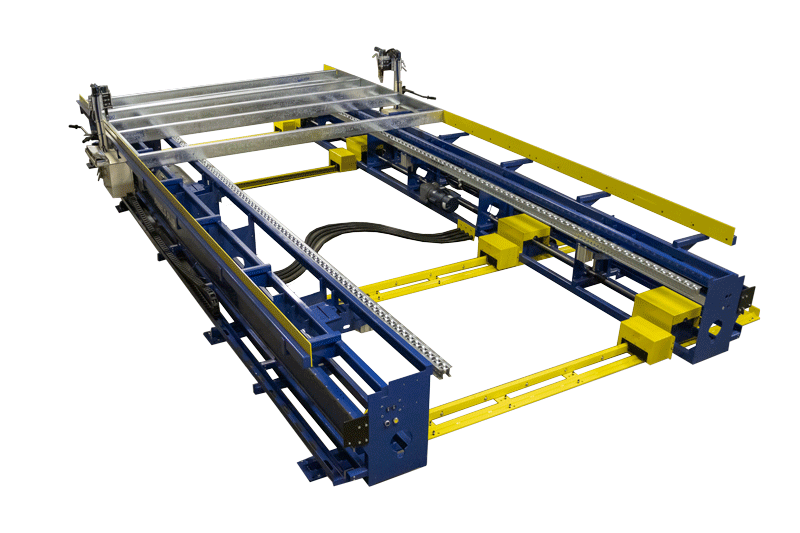

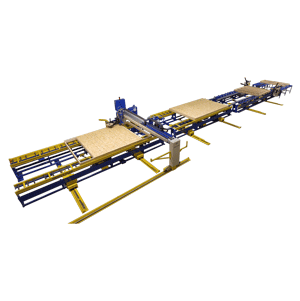

The Industry-Leading Manufacturer of Panelized

Wall Panel & Floor Cassette Equipment

IMPROVE CONSISTENCY | INCREASE EFFICIENCY

WHO WE ARE

Proudly made in the USA for over 20 years, Panels Plus designs and manufactures panelizing equipment for constructing wall panels, floor cassettes, and associated subcomponents in the off-site, modular, and prefabricated building industries. Our equipment reduces labor while improving product consistency and employee safety, making us a leader in the industry.

Welcome to Panels Plus.

We Nailed It.

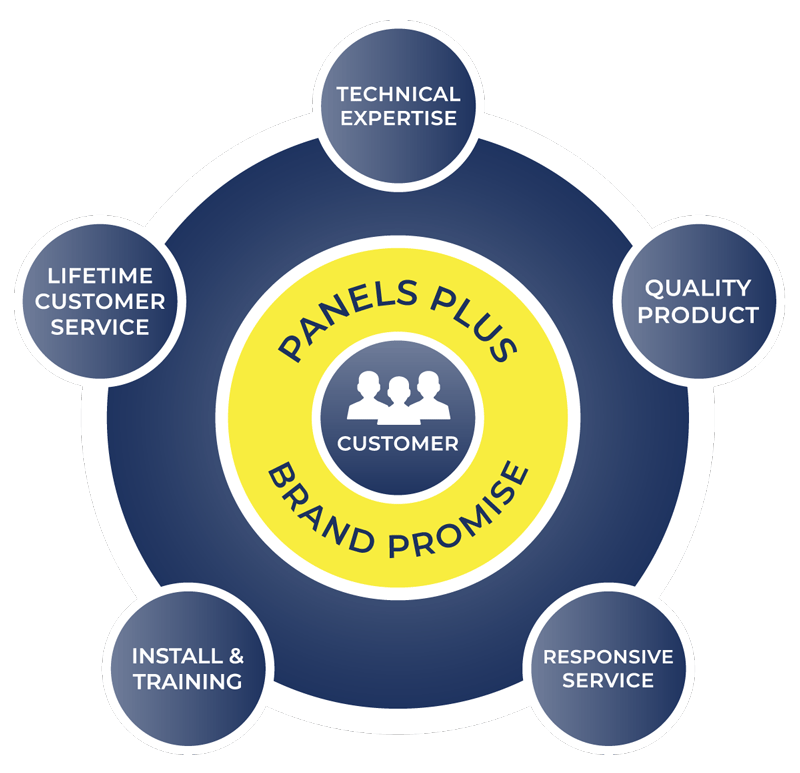

THE PANELS PLUS PROMISE

We promise to support our customers for as long as they own Panels Plus equipment. Whether you’re a startup plant and need technical expertise, or you’re seasoned in the off-site, modular, and prefabricated building industries and are planning to integrate panelizing equipment into your existing lines, Panels Plus will be here to help ensure your success.

Technical Expertise & Assistance | Installation & Training | Customer Support

EMPLOYEE-OWNED ADVANTAGE

Located in Albert Lea, Minnesota, our organization is 100% employee-owned. Our team is passionate, knowledgeable, and absolute experts at what they do. At Panels Plus, we believe that when employees are owners, that makes everything in the customer experience better. While we are proud of the equipment and capabilities inside our facility, our greatest asset, and the reason our customers trust Panels Plus, will always be our people.

TESTIMONIALS

We can really see how Panels Plus are making their mark on the Industry. Prompt service, willingness to listen and help makes them a great company to do business with.

Thank you for the great job you and your team provided for our company. Leigh did a great job on the install. We were up and running in one day. The bridge works great. It has improved the quality of our panels. The nails and staples are in perfect rows and spaced correctly. This has reduced the time we spent re-nailing missed studs and misfires. We take pride in making sure our customers get the best quality product we can provide and this equipment has helped us reach this goal.

It has been great working with Panels Plus for the past 18 years. Their equipment in my eyes is the best out there. It performs as expected, durable and it is easy to operate. From the design and engineering department to the employees assembling the equipment to the sales personnel. When you visit their shop you always feel welcome and can answer any questions that you might have. Top notch Panels Plus and keep up the good work.

So much easier to train new employees with easier to read and bigger buttons. With “nine” presets for the sheathing and the height allows the operator to be more efficient in the set up process. Having the bridge and carriage home simultaneously cuts the homing time in half. Overall, the new screen design is a major improvement over the previous screen. As the production supervisor it allows me to rename the sheathing and the height buttons to specific jobs so the operator only needs to know the name of the job, press the buttons, and with that name start operating the machine. We use numerous types of sheathing with panels that range from 8’0” to 12’0” which makes this feature a “Plus”.