ACCESSORIES

As North America’s leader in semi-automated, panelized wall panel and floor cassette equipment, Panels Plus offers a variety of accessories to assist and optimize the manufacturing of wall panels and floor cassettes.

Most accessories featured on this page can be purchased as a stand-alone product or can be integrated into a station or production line as an optional upgrade to assist in production.

Panels Plus accessories are ideal for companies that manufacture panelized wood and steel wall panels, such as off-site building manufacturers, manufactured home builders, and modular builders.

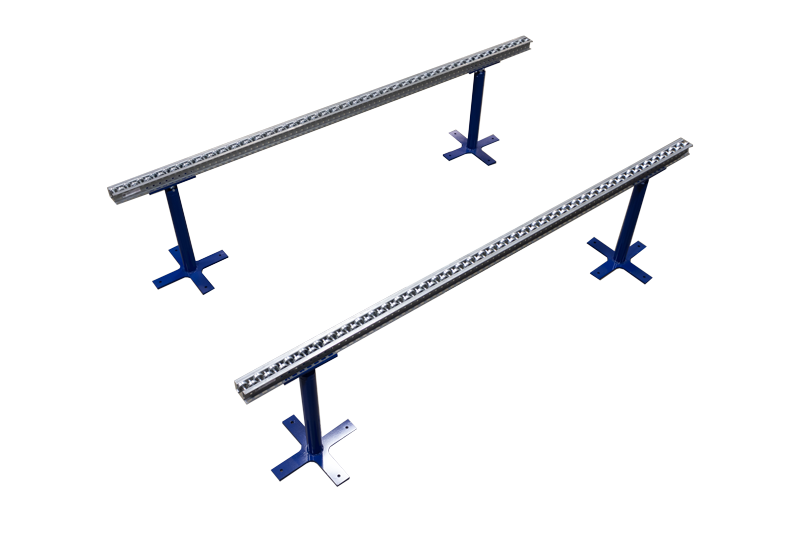

Roller Conveyors transport subcomponents and wall panels between stations with ease. The Panels Plus roller conveyors are placed between stations to transport subcomponents and wall panels between the various stations.

In addition to moving product down the production line, roller conveyors act as a buffer zone between stations while other panels are being constructed. They can also be placed at the end of a production line to hold wall panels while they await stacking for shipment.

Roller conveyors are stationary and can be manually adjusted to match the height of your station or system, making it easy to transition subcomponents and wall panels to your desired location. They can also be placed back-to-back to extend your buffer zone.

Adjustable Height: 31’’ to 35’’ high

Standard Lengths: 10’, 15’, 20’

Benefits

- Easily transport subcomponents and wall panels

- Buffer zone between tables

- Ergonomic Height

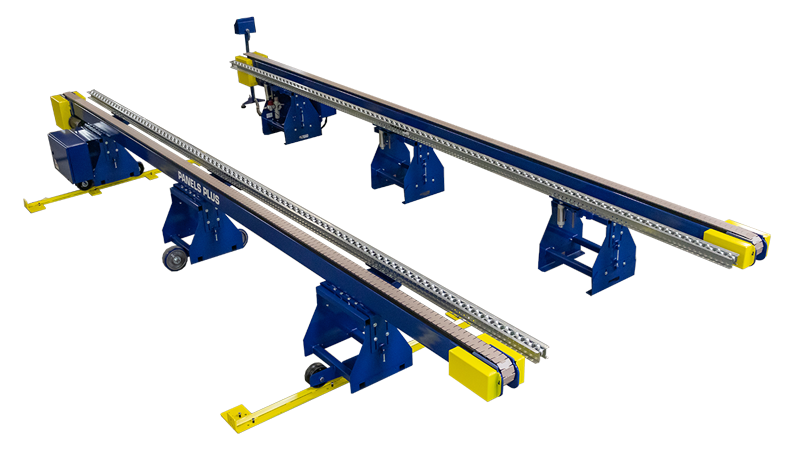

With a simple push of a button, you can transport subcomponents and wall panels hands-free with Panels Plus Power Conveyors. Like the Roller Conveyors, Power Conveyors are used for conveying and staging walls between stations and moving wall panels down the production line.

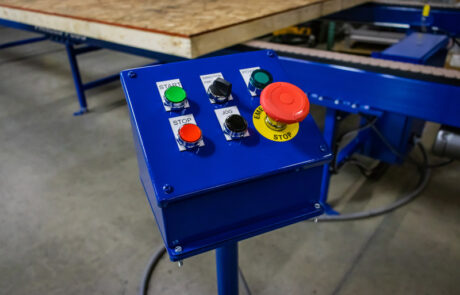

Power Conveyors are operated by a movable control pedestal. The pedestal has has push-button controls, a directional selector switch, and an emergency shutoff button.

Power conveyors are an optional upgrade from roller conveyors and can be integrated into any of the Panels Plus wall panel and floor cassette systems.

Benefits

- Hands-free transport of subcomponents and wall panels

- Low friction tabletop conveyor chain

- Moveable control pedestal

Subscribe to our channel by clicking the button below.

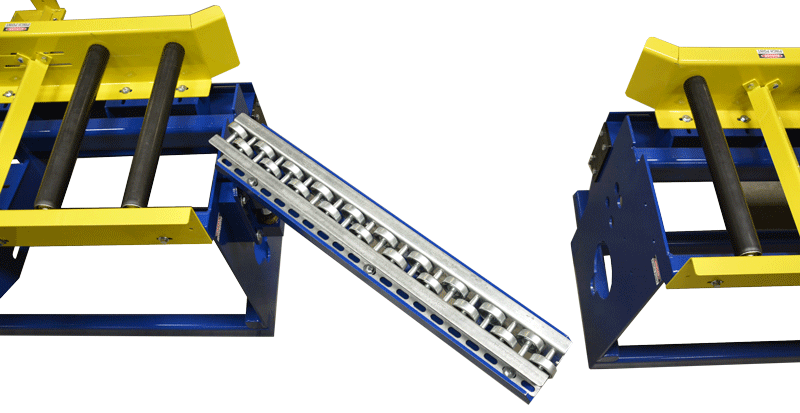

Swing gates bolt onto either end of the Panels Plus stations and allow subcomponents and wall panels to roll freely from station to station without having to be lifted.

The swing gates allow walk-through passage between stations and swing back after someone walks through. This prevents product from dropping between the stations. The Swing Gates allow operators to move from one side of the line to the other without having to walk around the entire system line.

Benefits

- Easily transport subcomponents and wall panels between stations

- Walk-through passage between stations

The Panel Lift is used to lift panels at the end of the production line and stack them for shipment. The center lift connection allows for balanced lifting with a ceiling hoist or forklift.

The lift arms can be easily adjusted for varying panel heights by moving a single pin, lifting 7’ to 12’4” panels. The panel lift also features end handles for convenient grasping points for the manual movement of panels.

Benefits

- Easily adjusted for varying wall heights

- Lift handles allow easy manual panel movement

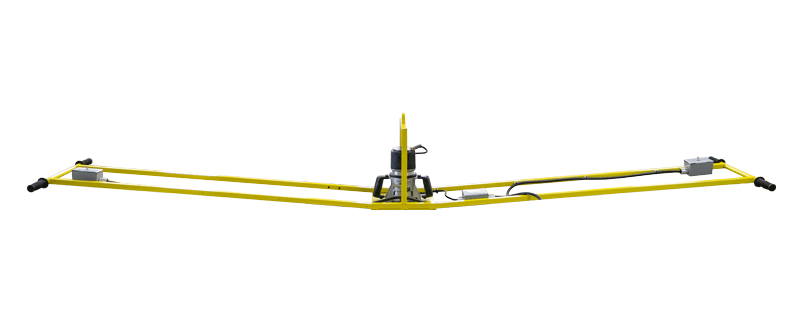

The Handlebar Router is a low-cost option for those who don’t want to purchase a routing bridge.

The Handlebar Router is used in conjunction with the Squaring Station and Combo Station. Two operators hold the handlebars on either end to cut out rough openings. The extended control arm allows operators to reach panel edges without having to climb on top of the panel.

This product features a 3.25 HP router with a plunge bit. The Handlebar Router has router power control on both ends, so both operators are able to turn the router on and off.

Benefits

- Lightweight and ergonomic design

- Router control on both ends

- Low-cost routing option

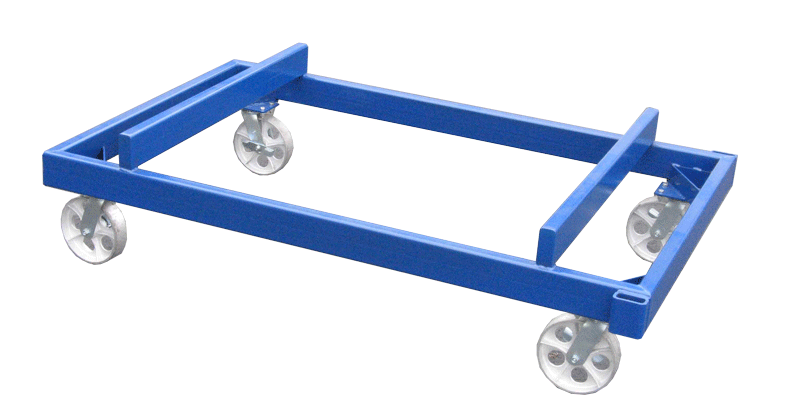

BULK CART

The Bulk Cart is designed for on-site assistance during wall panel and floor cassette construction.

The Bulk Cart is designed to hold up to the rigors of a panel shop. With a welded steel construction and wheels, this cart can assist in staging materials and work as a place holder for product. Use it to keep bunks of lumber, wood and steel components, plates, and sheathing at-the-ready.

Benefits

- Steel construction

- Easily move components, bunks of studs, plates, and sheathing

TREE CART

The Tree Cart is built to house and store the various components needed to complete the construction of wall panels and floor cassettes. It is designed to hold pre-marked studs and various cut components for rough openings.

Use the Tree Cart as a staging area and place it near your plate-marking saw or near your production line to efficiently organize materials. Organize your materials in order of their use for a more-efficient manufacturing process.

Benefits

- Staging area for subcomponents and panels

- Steel construction

- Wheels for easy movement