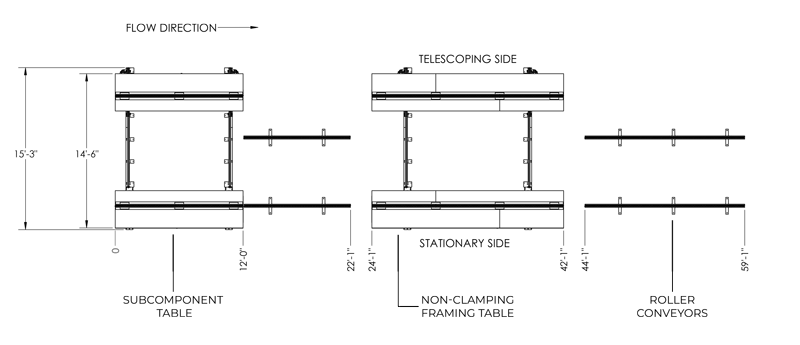

The Interior Hand Framing Line is ideal for customers that want to manually fasten wall panels by hand. This line is also compatible with those using plate-marking saws. This production line features a Non-Clamping Framing Station, Subcomponent Table, and Roller Conveyors.

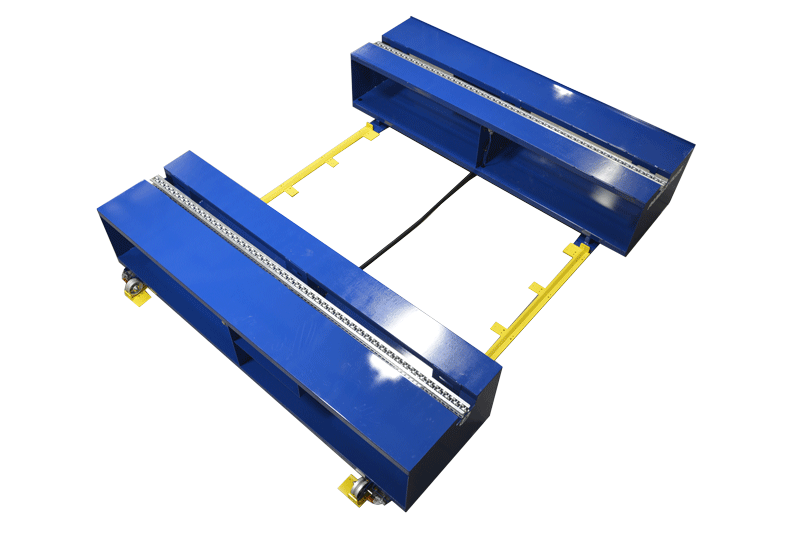

A Subcomponent Table is placed at the beginning and middle of the line. They are used to build rough openings and manufacture wall panels by hand nailing. The Subcomponent Table has pop-up rollers, a squaring edge, and a telescoping side that manually rolls in and out to set the subcomponent height. This 18’ non-clamping table closes down to 7’ and opens up to 14’.

The Subcomponent Table provides an ergonomic elevated space for hand nailing wall panels and is an upgrade from traditional panel building methods like working off the ground.

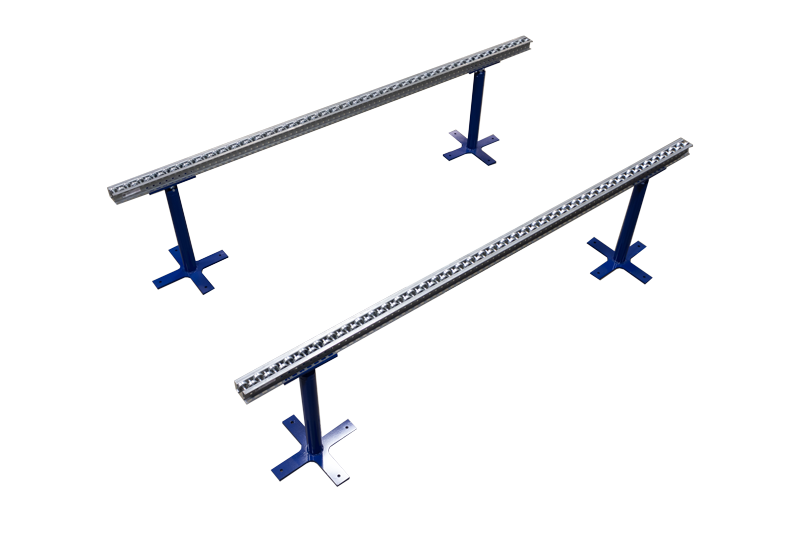

Roller Conveyors transport subcomponents between systems and act as a buffer zone while other panels are being constructed. They also can be placed at the end of line to hold wall panels while they await stacking.