ROUTING STATION

Quality Panels, Every Time

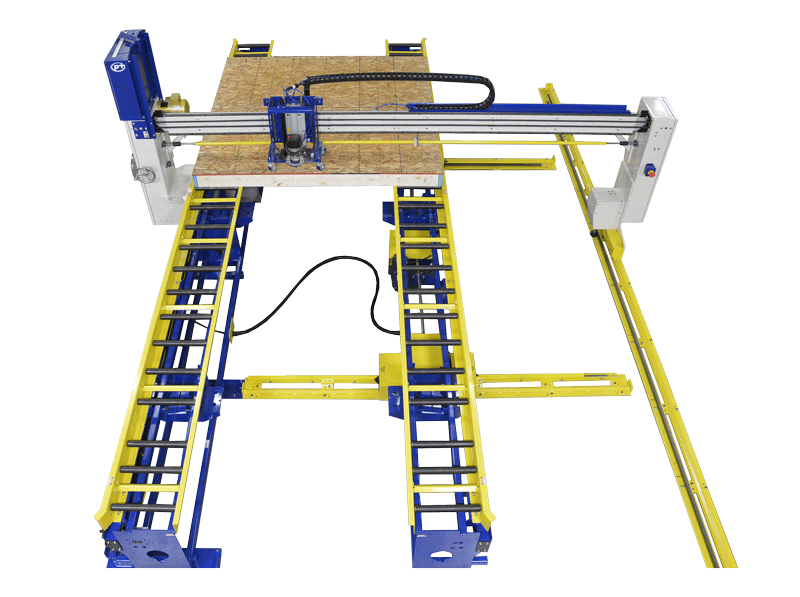

The Routing Station incorporates a manual X-Y router bridge with the Panels Plus Squaring Station. This model consists of a squaring table designed to hold wall panels square while sheathing is tacked in place and rough openings are routed out, ensuring quality panels every time.

The manual X-Y router bridge is available in 120v or 230v 3ph. This model can be stand-alone or integrated into a full production line. Various sizes and configurations are available.

Benefits

- Ergonomic working height

- Single person operation

- Router bridge easily cuts out rough openings

- Improved employee safety

Routing Station

With the Panels Plus Routing Station, you are one step closer to more automation. The Routing Station incorporates the Panels Plus Squaring Station with a manual X-Y router bridge. It is designed to hold wall panels square while sheathing is tacked in place and rough openings are cut out. The manual X-Y router bridge is available in 120v or 230v 3ph. This station is ideal for companies that manufacture wood wall panels, such as off-site building manufacturers, manufactured home builders, and modular builders.

The Panels Plus wall panel systems are more ergonomic than traditional construction methods and are developed at an ergonomic working height. This eliminates the need to continually kneel or hunch over to build wall panels – improving employee health and safety.

How It Works

After a wall panel has been framed, it is rolled into the Routing Station. This squaring station model consists of a manual X-Y router bridge and a squaring table with various features including squaring stops, horizontal rollers, footswitch, push-button controls, stationary side, and a motorized telescoping side.

When loading the panel into the squaring station, the squaring stops tip down to allow the panel to roll into the squaring table. Once the panel passes the squaring stops, the stops tip up to create a 90-degree stop. The panel is then pulled back against the stop and clamped to ensure squareness without having to manually measure for squareness.

The telescoping side is guided by tracks on the floor to set the panel height. The wall panel is clamped against the squaring edge using the footswitch on the load end of the squaring table.

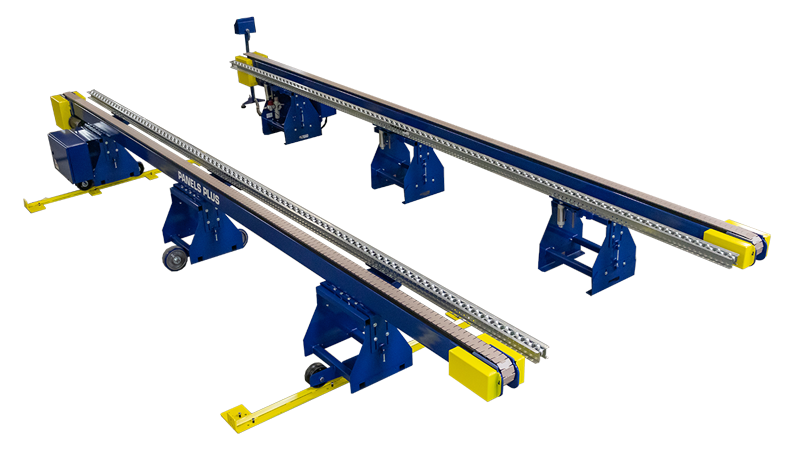

Once the wall panel is square, sheathing is tacked in place by hand. When not using pre-cut sheathing, the manual X-Y router bridge is used to cut any rough openings. Power conveyors are an optional upgrade to move wall panels hands-free between workstations.

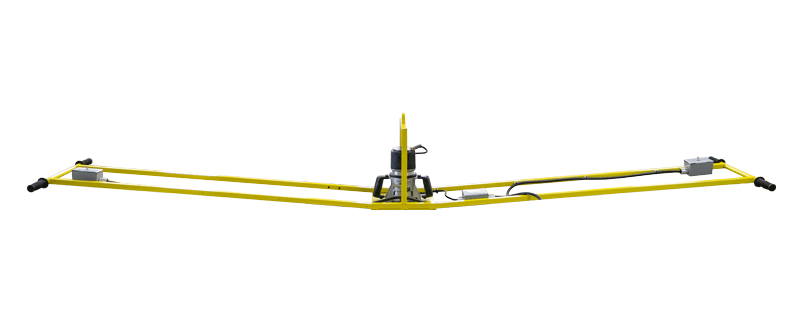

Manual X-Y Router Bridge

The router bridge turns a 2-person job into a 1-person operation. The manual X-Y router bridge features two hand cranks to move the router in the X and Y directions. The bridge is equipped with a pendant to drive the bridge into position and has an auto-return feature to return the bridge to its home position with the push of a button.

Along with an ergonomic working height, the router bridge is built with safety in mind and includes an emergency shutoff button on both sides of the bridge, a well as trip cables that deactivate the system if activated.

Squaring and Routing Station Specs

| 120v Router | • 120Vac/60Hz/15amp |

| 3Phase Router | • 230V 3ph 5 wire |

| Air | • 10 CFM @ 90-120psig |

| Standard Machine Length and Width | • 22’Long x 17’ 6”Wide • Various sizes and configurations are available |

| Wall Panel Size | • 4’ to 12’4” Tall Wall Height • Up to 16’ Long • Various table sizes and configurations are available |

| Compatible Materials | • Lumber from 2×4 to 2×10 |

| Working Height | • 33” roller height |

| Framing Table Construction | • Welded steel construction |

| Telescoping Side | • Adjusted in and out to set panel height |

| Squaring Stops | • Located on each side of the load end • Tip down when loading the table • Tip up once table is loaded to create a 90-degree corner • Ensures squareness of wall panels |

| Footswitch | • Located at the load end of the squaring table • Clamps/unclamps the squaring table |

| Push-Button Controls | • Located at exit end of the squaring table • Clamps/unclamps the squaring table |

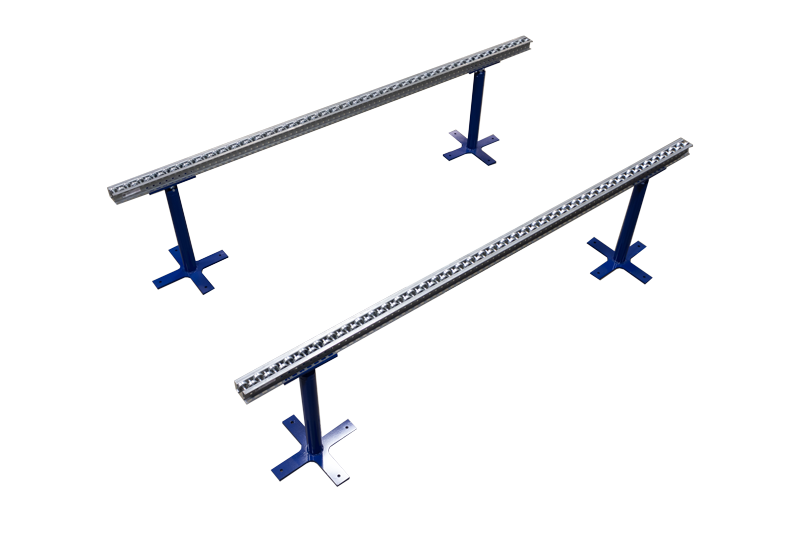

| Horizontal Rollers | • Extend the entire length of the table • Allows easy panel movement down production line |

| Manual X-Y Router Bridge | • Pendant to control bridge position • Manual hand cranks (2) • Push-Button functionality |

| Manual X-Y Router Bridge Safety Features | • Emergency shutoff (both ends of bridge) • Trip cables |