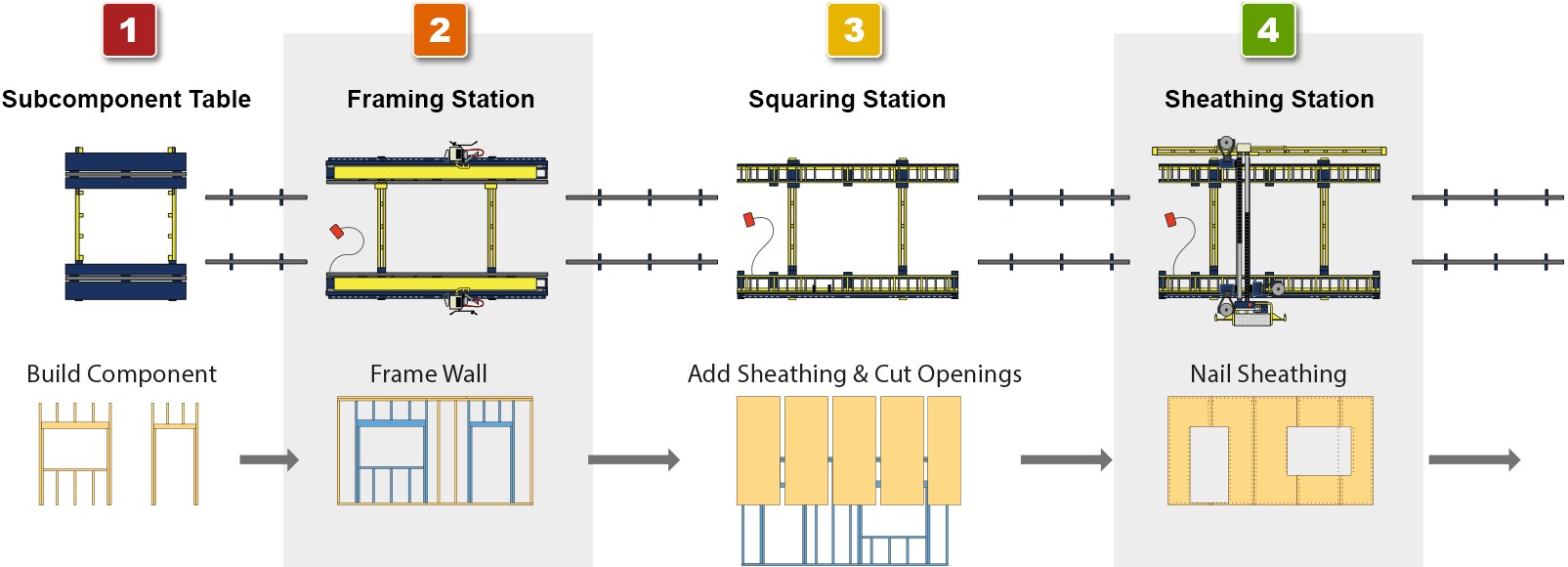

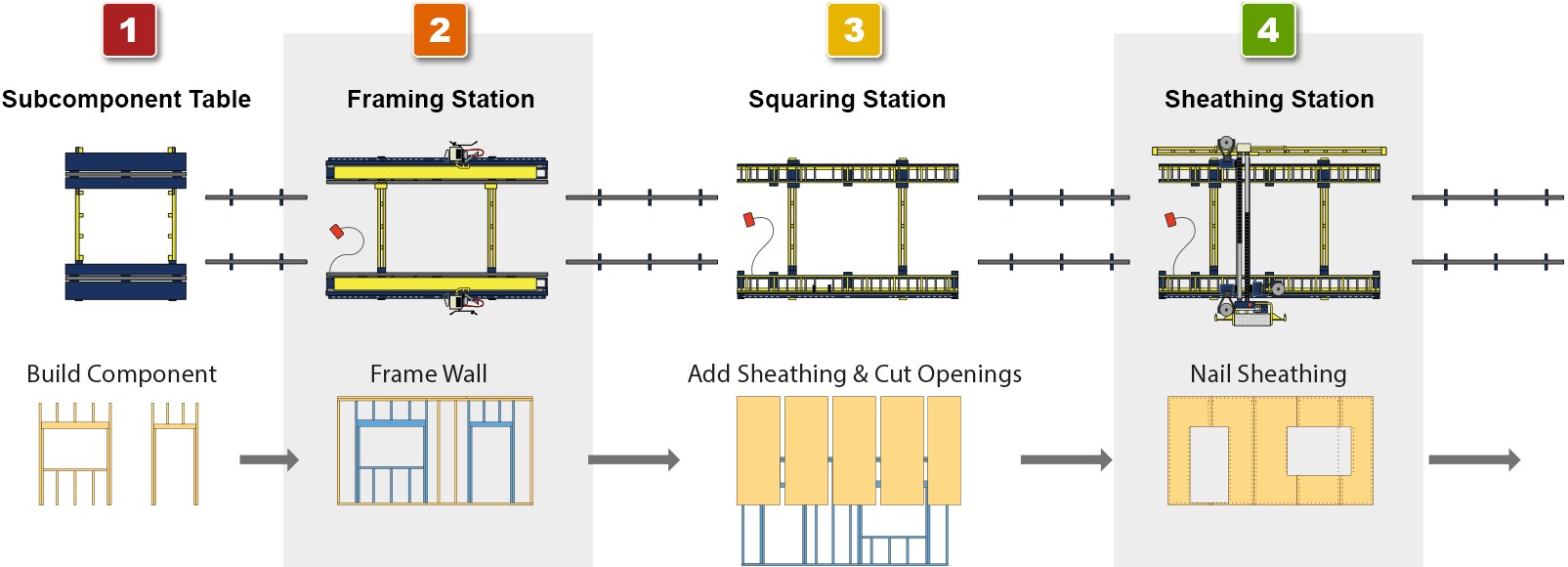

The Panels Plus 3-Table Line is also known as a Full Production Line. It has the largest footprint and the highest production output in comparison to the other system lines. The 3-Table Line frames and sheathes wall panels. This production line consists of a Framing Station, Squaring Station, Sheathing Station, Subcomponent Tables and Roller Conveyors.

WORKING STATIONS in a PRODUCTION LINE

SUBCOMPONENT TABLE

The Subcomponent Table is available in two sizes, 12′ and 18′. Placed at the beginning of the production line, this product is used to build rough openings. It has pop-up rollers, a squaring edge, and a telescoping side that manually rolls in and out to set the component height. These tables can be adjusted to match the height of your station or system, making it easy to transition subcomponents from the tables to your desired location.

FRAMING STATION

The Framing Station is the first machine in the 3-Table Line and holds the plates, subcomponents, and studs squarely in place for fastening. Panels Plus offers three different Framing Stations: Non-Clamping Framing Station, Framing Station with Locators or Wide Plate Framing Station.

The Framing Stations can be ordered with or without indexing tool carriages. The carriages semi-automatically fasten the top and bottom plates to the studs with the press of a single button.

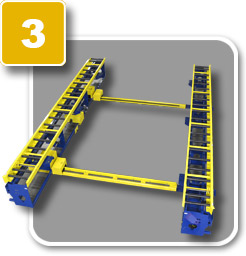

SQUARING STATION

The Squaring Station is the second machine in the 3-Table Line and holds the wall panel square while sheathing is tacked in place. In this production line, rough openings are routed out by hand.

**For a more automated option, view our 3-Table Router Line.

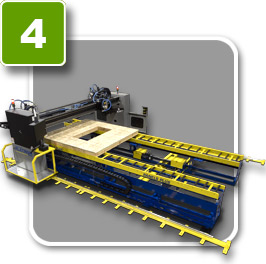

SHEATHING STATION

The Sheathing Station is the last machine in the 3-Table Line and is designed to fasten sheathing to wall panels. It features a single tool bridge that smoothly traverses the wall panel, shooting nails at a preset spacing. The Sheathing Station also has a touchscreen with 9 presets to easily change fastener spacing.

The Sheathing Station can be ordered as a Single Beam Sheathing Station with plate stitchers, a Dual Beam Sheathing Station, or our fully automated Platinum Series Sheathing Station.

The plate stitchers offer flexibility in fastener spacing while stitching the top and bottom plates.

CONVEYORS and POWER CONVEYORS

Conveyors are available in two options, manual and powered. They are placed between stations to transport subcomponents from one station to another, and to act as a buffer zone while other wall panels are being constructed. They are also commonly placed at the end of a system line to hold wall panels while they await stacking.

PRODUCTION BOOSTING ACCESSORIES

TILT TABLE

Tilt Tables allow operators to access both sides of the wall panel by pneumatically lifting the panel to 75 degrees, making the installation of blocking, windows or insulation easy. Tilt Tables have a built-in squaring feature allowing it to replace a Squaring Station in a production line.