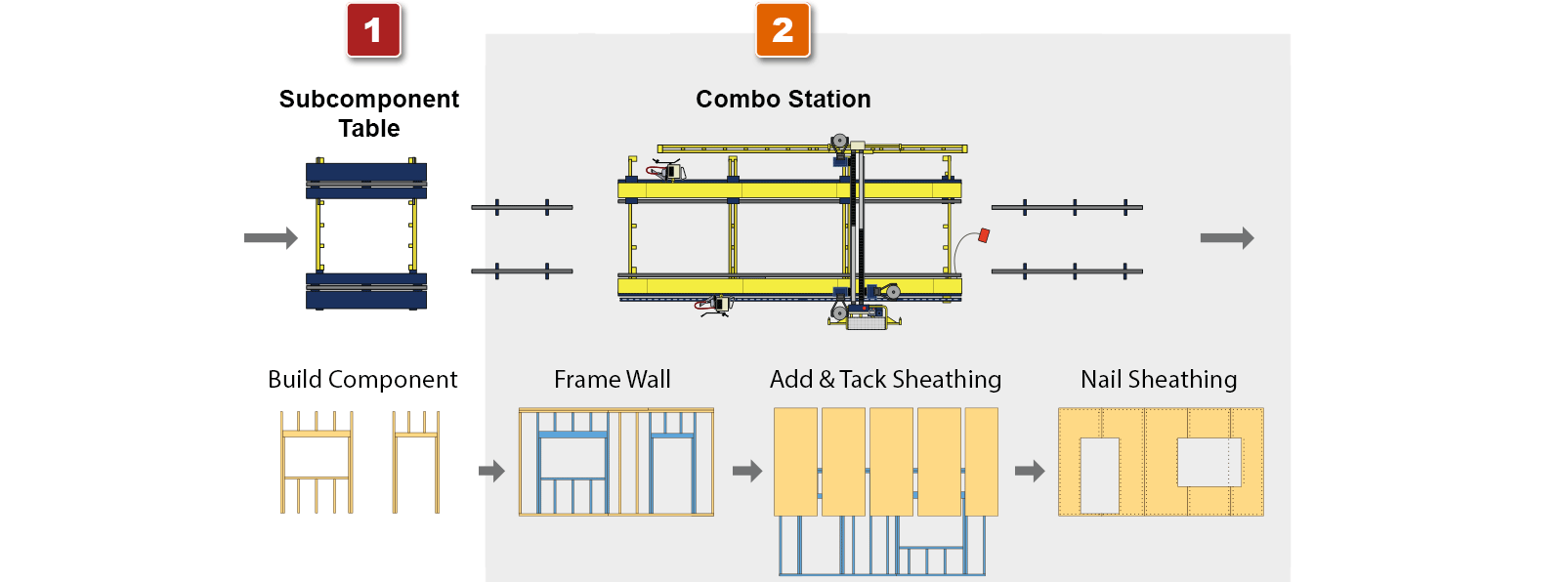

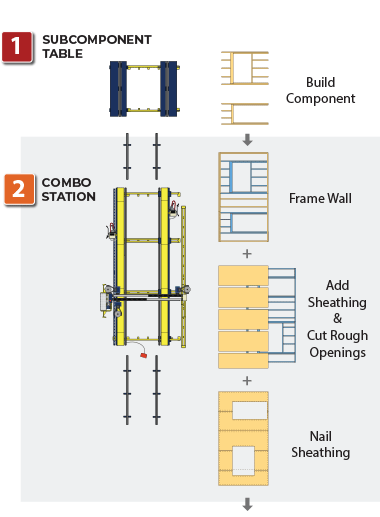

The Combo Production Line is a great solution for builders who are just getting into wall panel construction, and for companies with facility size restrictions. This 2 station line consists of a Subcomponent Table and a Combo Station that allows operators to sheath, route, and sheath panels all on one machine.

WORKING STATIONS in a COMBO PRODUCTION LINE

SUBCOMPONENT TABLE

The Subcomponent Table is available in two sizes, 12' and 18'. Placed at the beginning of the production line, this product is used to build rough openings. It has pop-up rollers, a squaring edge, and a telescoping side that manually rolls in and out to set the component height. These tables can be adjusted to match the height of your station or system, making it easy to transition subcomponents from the tables to your desired location.

COMBO STATION

The Combo Station frames and sheathes wall panels all in one system. It consists of a combo table, single tool sheathing bridge, and indexing tool carriages. The combo table is available with either stud locators or wide projection plates for stud placement. Stud locators offer quick and precise stud placement, while wide projection plates are designed for manufacturers equipped with a laser projection system, or for those using a plate-marking saw.

CONVEYORS and POWER CONVEYORS

Conveyors are available in two options, manual and powered. They are placed between stations to transport subcomponents from one station to another, and to act as a buffer zone while other wall panels are being constructed. They are also commonly placed at the end of a system line to hold wall panels while they await stacking.

Conveyors are available in two options, manual and powered. They are placed between stations to transport subcomponents from one station to another, and to act as a buffer zone while other wall panels are being constructed. They are also commonly placed at the end of a system line to hold wall panels while they await stacking.