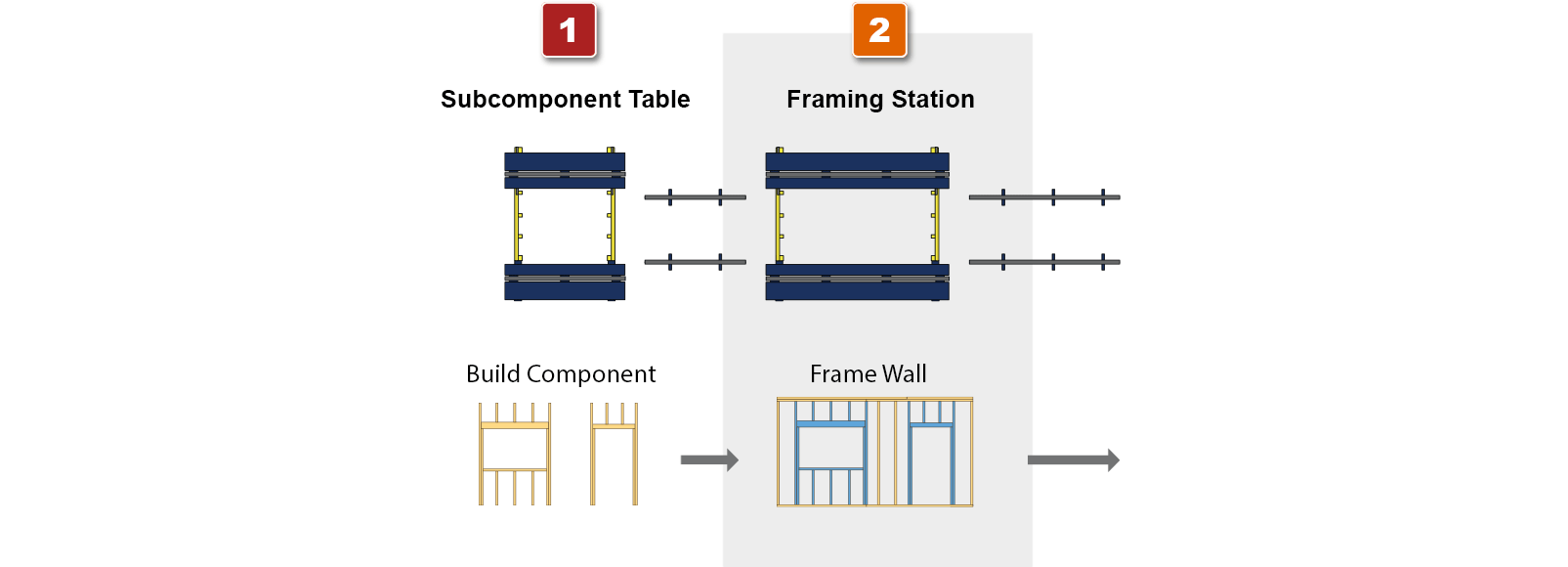

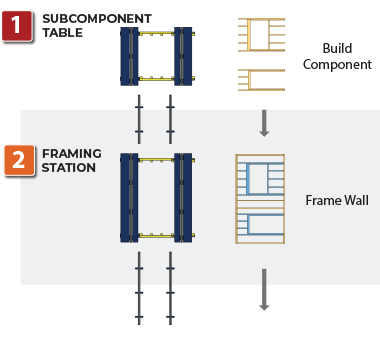

Designed for building interior wall panels, this production line is ideal for customers that want to run a line parallel to their exterior line to increase interior wall production capacity. With only one machine, the Interior Line is a great starting point for customers that are more budget-sensitive and want a system that can grow as their business grows. This production line consists of Subcomponent Tables, Framing Station, and Roller Conveyors.

WORKING STATIONS in an INTERIOR HAND FRAMING LINE

SUBCOMPONENT TABLE

The Subcomponent Table is available in two sizes, 12′ and 18′. Placed at the beginning of the production line, this product is used to build rough openings. It has pop-up rollers, a squaring edge, and a telescoping side that manually rolls in and out to set the component height. These tables can be adjusted to match the height of your station or system, making it easy to transition subcomponents from the tables to your desired location.

NON-CLAMPING FRAMING STATION

The Non-Clamping Framing Station is available in an 18′ foot configuration. Designed for hand framing wall panels, it has pop-up rollers, a squaring edge, and a telescoping side that manually rolls in and out to set the component height. Th station can be adjusted to match the height of your station or system, making it easy to transition subcomponents from the tables to your desired location.

CONVEYORS and POWER CONVEYORS

Conveyors are available in two options, manual and powered. They are placed between stations to transport subcomponents from one station to another, and to act as a buffer zone while other wall panels are being constructed. They are also commonly placed at the end of a system line to hold wall panels while they await stacking.