LIGHT GAUGE STEEL SHEATHING STATION

Quality Panels, Every Time

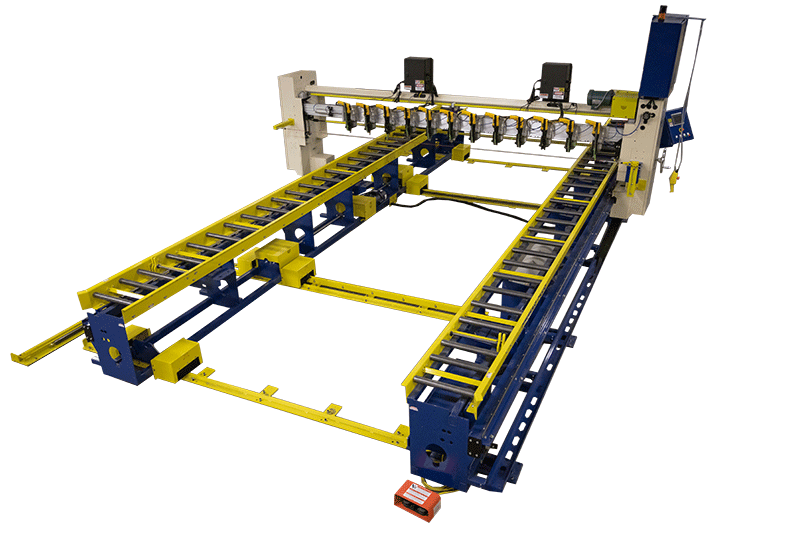

The Light Gauge Steel Sheathing Station offers flexibility in wall height, sheathing thickness, and screw spacing and screws sheathing to steel wall panels to ensure quality panels every time.

This model can be stand-alone or integrated into a full production line. Various sizes and configurations are available.

Benefits

- Ergonomic working height

- Single person operation

- Flexibility with fastener spacing

- Fastens consistently and accurately

- Improved employee safety

Light Gauge Steel Sheathing Station

The Light Gauge Steel Sheathing Station is designed to screw sheathing to steel wall panels to ensure quality panels every time. This model is ideal for companies that manufacture steel wall panels, such as off-site building manufacturers, manufactured home builders, modular builders, and panelized construction.

The Panels Plus panelized wall panel systems are more ergonomic than traditional construction methods and are developed at an ergonomic working height. This eliminates the need to continually kneel or hunch over to build wall panels – improving employee health and safety.

How It Works

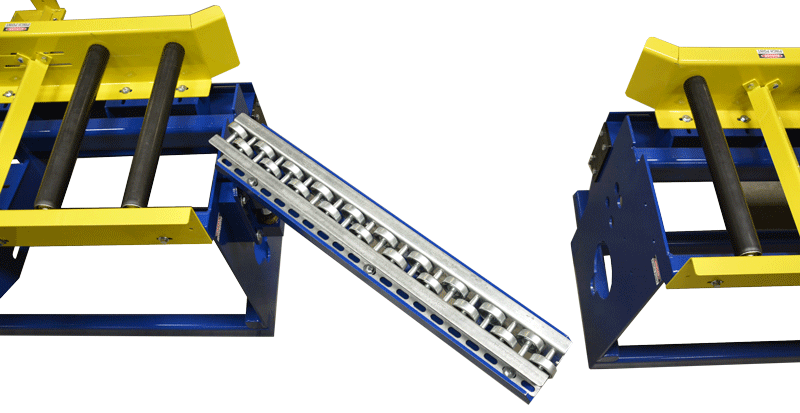

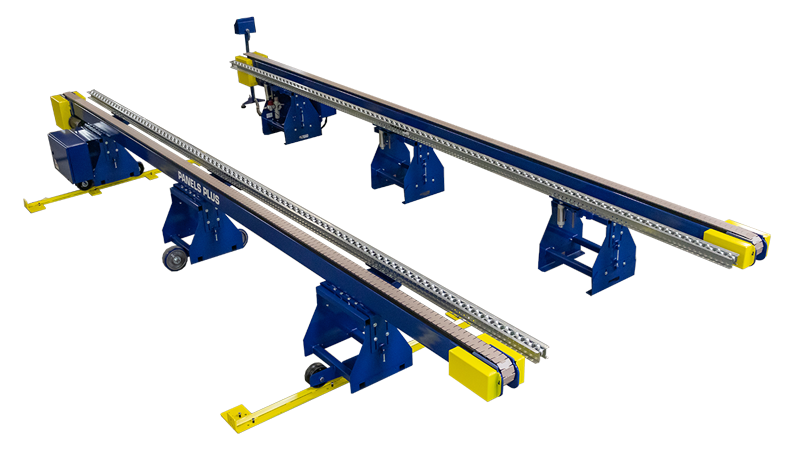

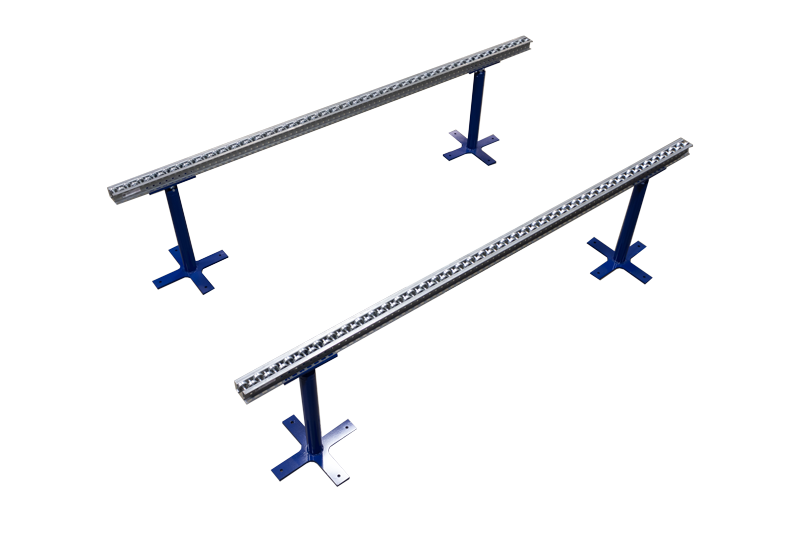

The Steel Sheathing Station is equipped with a squaring table and multitool steel sheathing bridge. After the wall panel has been framed and squared, it is rolled into the squaring table via roller conveyors. The squaring table includes a squaring edge, horizontal rollers, footswitch, push-button controls, a stationary side, and a motorized telescoping side.

Once the wall panel is loaded, the telescoping side is guided by tracks on the floor to set the panel height. The wall panel is re-clamped against the squaring edge by stepping on the footswitch on the load end of the table or by push-button controls on the exit end of the squaring table. This holds the steel wall panel square during the sheathing process.

When the steel wall panel is sheathed, it is easily moved down the production line via the roller conveyors. Power conveyors are an optional upgrade to move wall panels hands-free between workstations.

Multitool Sheathing Bridge

The multitool sheathing bridge is equipped with a handheld control pendant that assists with moving the bridge to the next screw placement. There is also a hand crank wheel for fine-tune movement. The multitool sheathing bridge uses electric screw tools to screw sheathing to the steel wall panels at preset fastener spacing. The multitool sheathing bridge also has an auto-return feature.

Light Gauge Steel Sheathing Station Specs

| Electrical | • 230v 3ph |

| Air | • 40-60CFM @ 90-120psig |

| Standard Machine Length and Width | •22’L x 17’6’’W Various sizes and configurations are available |

| Wall Panel Size | • Table will sheath 6’6” to 12’ walls up to 16’ long • Handles wall thickness from 4’’ to 8’’ • Various sizes and configurations are available |

| Working Height | • 32.5’’ roller height |

| Sheathing Station Construction | • Welded steel construction |

| Multitool Sheathing Bridge | • Touchscreen to set wall height, sheathing thickness, and screw spacing • Handheld control pendant for X and Z axis bridge operation • Laser indicator for bridge alignment • Auto-return to the home position |

| Tooling | • Electric screw tools • Tool spacing to be determined by customer |

| Telescoping Side | • Adjusted in and out to set panel height |

| Squaring Edge | • Ensures squareness of wall panels |

| Footswitch | • Located at the load end of the table • Clamps/unclamps the table |

| Push-Button Controls | • Located at the exit end of the table • Clamps/unclamps the sheathing table |

| Horizontal Rollers | • Extend the entire length of the table • Allows easy panel movement down the production line |