SHED COMBO STATION

Benefits

- Multiple runner placements

- Fastens consistently and accurately

- Ergonomic working height & optional operator walkway

- Improved squareness vs. traditional methods

- Flexibility with fastener spacing

- Improved employee safety

Shed Combo Station

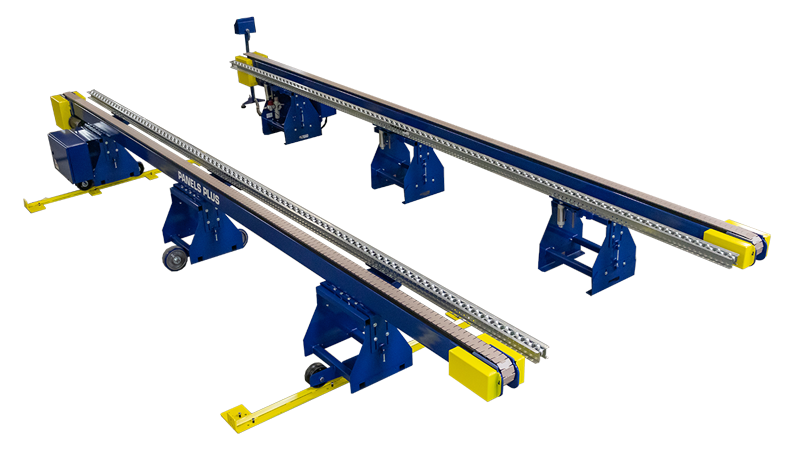

The Shed Combo Station is an all-in-one system designed specifically for the portable building industry.

This system frames, squares, and sheathes both wall and floor panels, and offers multiple runner placements – making it suitable for various building sizes.

The Panels Plus panelized wall panel systems are more ergonomic than traditional construction methods and are developed at an ergonomic working height. This eliminates the need to continually kneel or hunch over to build wall panels – improving employee health and safety.

How It Works

Designed to accommodate runners, the Shed Combo Station offers multiple runner placements. Once the machine is loaded, it holds the floor or wall square for framing and sheathing.

The Shed Combo Station is equipped with indexing tool carriages. This allows the operator to select the lumber size and press a single button to easily nail the rim boards to the joists for constructing floors or nail the plates to the studs for building walls.

After the floor has been framed, the tongue and groove sheathing is tacked on the floor frame. The operator then uses the touchscreen on the sheathing bridge to preset fastener spacings. With the touchscreen, you can toggle between various presets and easily change the fastener spacing. The bridge is driven up and down the wall on a mounted v-track using the manual joystick. To assist in positioning the bridge at each stud, there is a laser pointer that projects a line on the plate where the fasteners are inserted.

After the cycle is complete, the stitchers are used to nail the flooring to the rim joist while the bridge returns to its home position.

Once the floor or wall is completed, it is easily picked up or rolled out of the machine – allowing an operator to get started on the next floor or wall while they are getting the completed panel off the line.

Shed Combo Station Specs

| Electrical | • 120Vac/60Hz/15amp |

| Air | • 30 CFM @ 90-120psig |

| Standard Machine Length and Width | • 57’ L x 22’ W • Various sizes and configurations are available |

| Wall Panel Size | • 7’3” to 16’6” H x up to 40′ L • Various sizes and configurations are available |

| Compatible Materials | • Lumber between 2×4 and 2×10 |

| Working Height | • 31’’ framing height |

| Indexing Tool Carriages (2) | • Semi-automated • Located on the stationary side & telescoping side of the table • Mounted on V-rail • Handlebars for easy operation • Fires nails into plates via the fire button on the handlebar • Offers precise fastener placement |

| Single Tool Sheathing Bridge | • Touchscreen • Joystick for bridge operation • Laser indicator for bridge alignment • Auto-return to the home position |

| Sheathing Bridge Safety Features | • Emergency stop cables on each side of the bridge • Emergency stop button on the operator platform |

| Table Features | |

| Telescoping Side | • Adjusted in and out to set panel height |

| Operator Walkway (Option) | • Provides a walkway down the middle of the machine, allowing the operator to walk down the center of the floor to fasten the joists to the runners |

| Table Motion Alarm (Option) | • Alarm sounds when table is opened and closed • Alerts operators for increased employee safety |

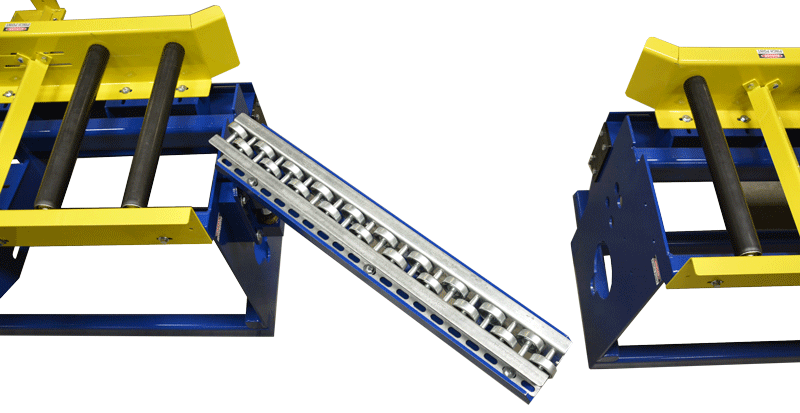

| Runner Supports | • Runs full length of table • When constructing a portable building with 4 runners, the supports allow the runners to remain straight (the center location is adjustable) |

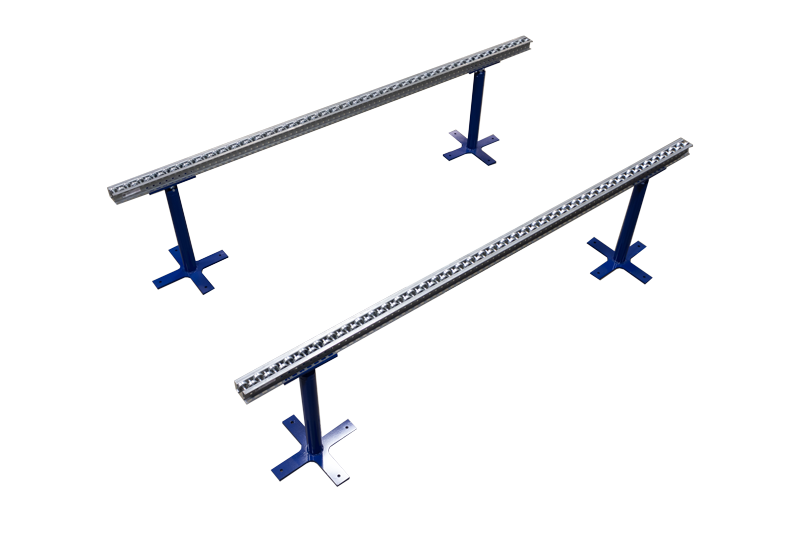

| Squaring Edge | • Ensures squareness of wall panels |

| Footswitch | • Located at the load end of the framing table • Clamps/unclamps the framing table |

| Push-Button Controls (2 Sets) | • Located at exit and load end of the framing table • Set 1 – Clamps/unclamps the framing table (on exit end) • Set 2 – Pops up roller conveyors (on both ends of the table) |

| Pop-Up Conveyors | • Extend the entire length of the table • Raised by push-button controls on either end of the table |