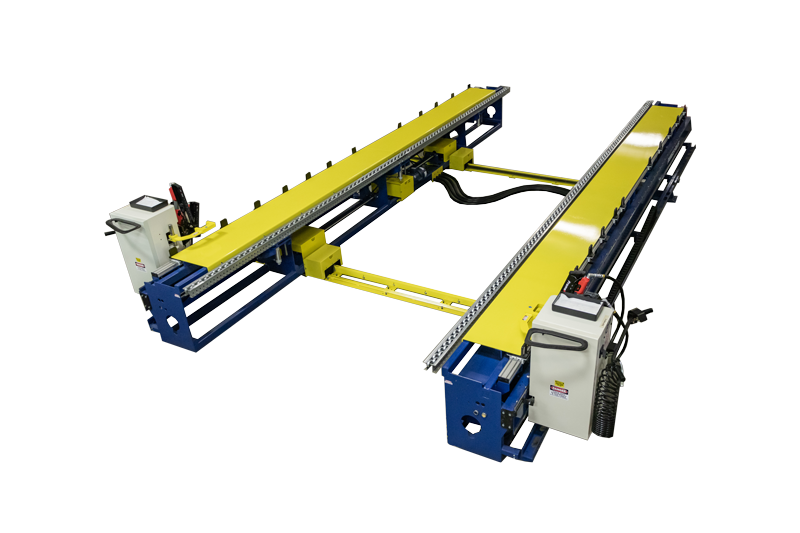

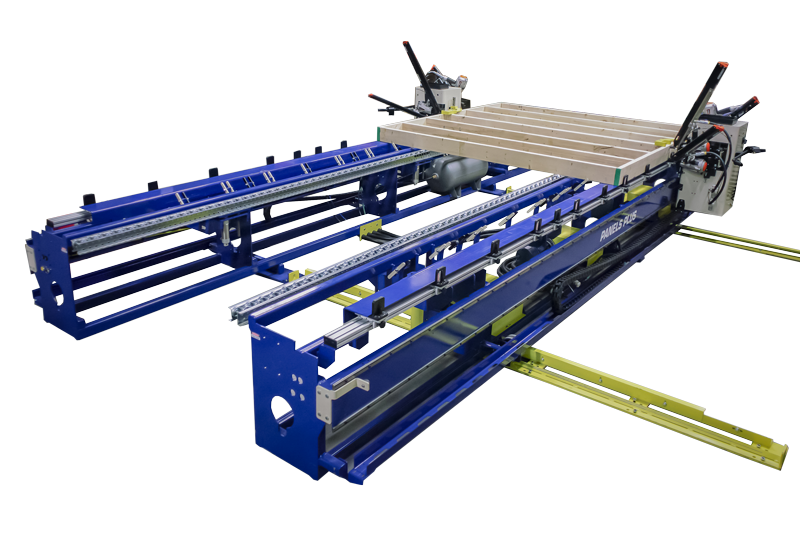

WOOD WALL FRAMING MACHINES

Built to Last

Wood Wall Framing Machines from Panels Plus offer more precise fastener placement, improved squareness, and overall consistency over traditional construction methods.

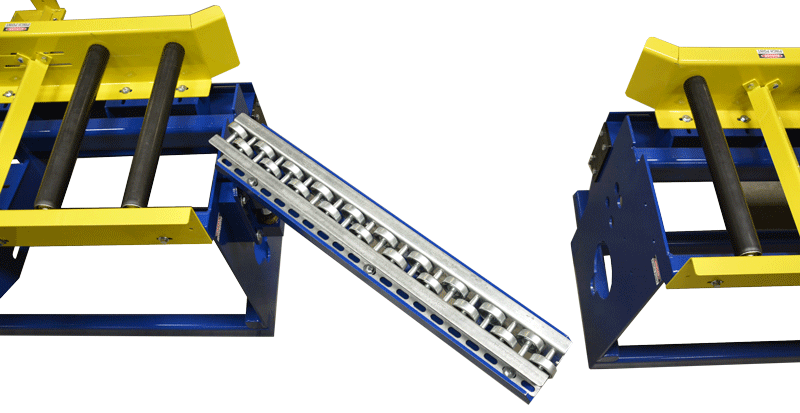

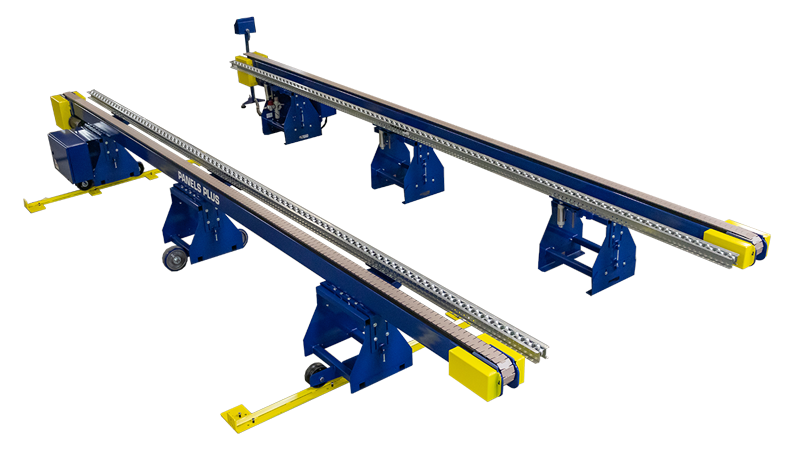

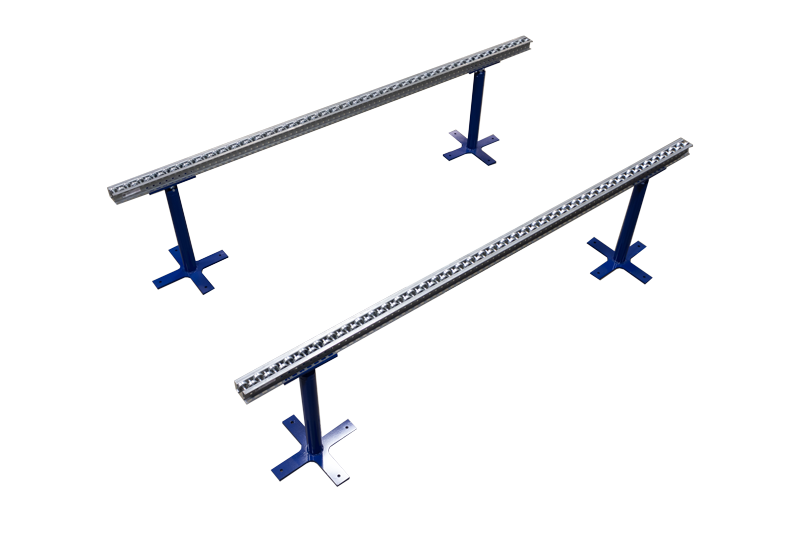

The Wall Panel Framing Table holds the plates, subcomponents, and studs squarely in place for fastening to ensure quality panels every time. It is designed to frame wall panels with lumber from 2×3 through 2×10. Designed with the rigors of a panel shop in mind, our panel manufacturing equipment is developed with longevity and quality. Many Panels Plus products built two decades ago are still in production today.

Wood Wall Framing Machines can be stand-alone or integrated into a full production line. Various sizes and configurations are available.