FLOOR CASSETTE STATION

Quality Panels, Every Time

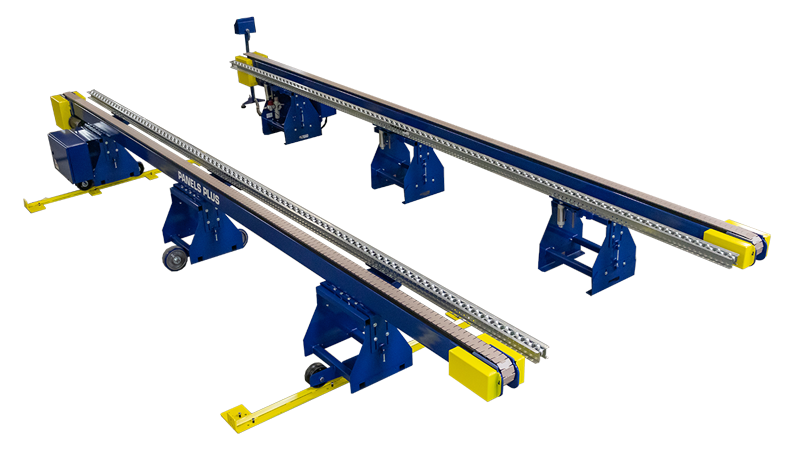

The Panels Plus Floor Cassette Framing Station is designed to hold joists in a square position for fastening decking. Dimensional lumber, I-joists, and open web floor truss configurations are all compatible with this cassette flooring system.

This model can be stand-alone or integrated into a full production line.

Benefits:

- Holds floor cassettes square

- Cassette floor panels pop up on completion and can be rolled out or picked up with a crane

- Improved employee safety

Floor Cassette Station

The Panels Plus Floor Cassette Framing Station is designed to hold joists in a square position for fastening decking. This model is ideal for companies that manufacture floor cassettes, such as off-site building manufacturers, manufactured home builders, and modular builders.

The Panels Plus cassette flooring system is developed at a lower working height, so fall protection is not required when fastening decking.

How it Works

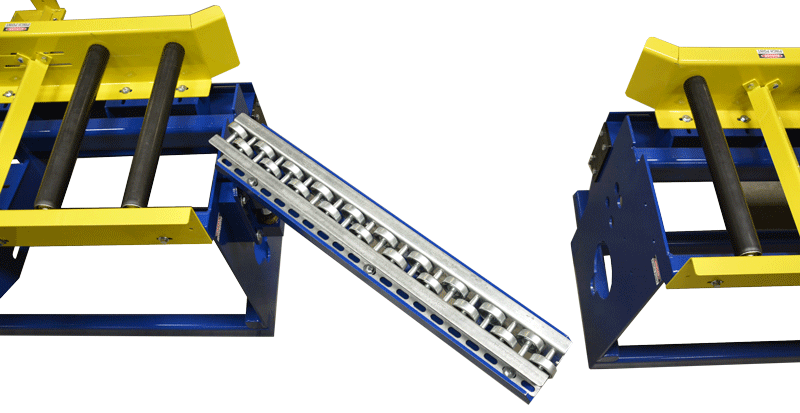

The Floor Cassette Station consists of a clamping table with various features including a squaring edge, joist locators, pop-up rollers, footswitch, push-button controls, stationary side, and a motorized telescoping side.

The telescoping side is guided by tracks on the floor to set the panel length. Joists are then manually loaded onto the clamping table using the joist locators. Locators can be spaced based on the customers’ needs and are color-coded for easy joist placement. The locators individually flip down if a joist comes out on top of them.

The floor cassette is clamped against the squaring edge by stepping on the footswitch on the load end of the table. This ensures the floor cassette is square before fastening. After clamping, operators apply the decking and then the decking is fastened by hand.

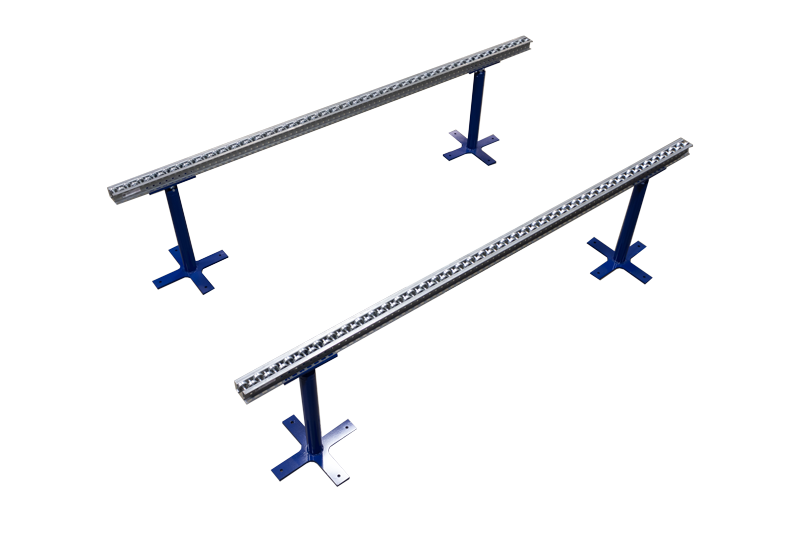

When the floor cassette is completed and unclamped, the floor cassette can be raised up on pop-up conveyors and either manually rolled out or picked up by an overhead crane.

Floor Cassette Station Specs

| Electrical | • 120Vac/60Hz/15amp |

| Air | •15 CFM @ 90-120psig |

| Standard Machine Length and Width | • 35’6”L (34’ floor) and 46’5” (45’ floor) L x 10’5”W (8’ wide floor) and 14’5” W (12’ wide floor) • Various table sizes and configurations are available |

| Standard Floor Panel Size | • Lengths: 34’ and 45’ long • 12’ and 8’ wide • Various length configurations are available |

| Compatible Materials | • Dimensional lumber, I-joists, and open web floor truss configurations |

| Working Height | • 24” Joist height base |

| Floor Cassette System Construction | • Welded steel construction |

Table Features |

|

| Telescoping Side | • Adjusted in and out to set cassette length |

| Joist Locators | • Locator spacing to customer’s needs • Color-coded for easy joist placement • Ensures consistency with joist placement |

| Squaring Edge | • Ensures squareness of floor cassettes |

| Footswitch | • Located on the stationary end of the table • Clamps/unclamps the table |

| Pop-Up Conveyors | • Extend the entire width of the table • Raised by push-button controls on the stationary end of the table |