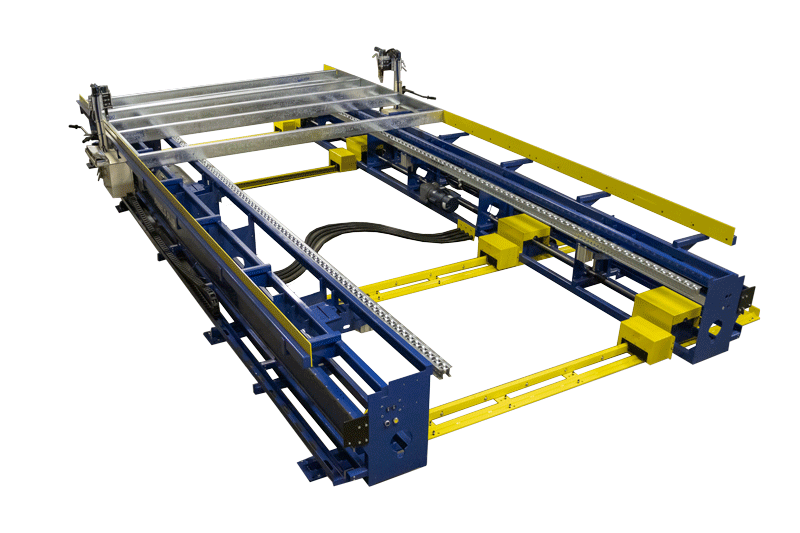

The Light Gauge Steel Framing Station is made up of a steel framing table and two screw tool carriages. To ensure consistently accurate results every time, the steel framing table holds the steel C-channels and tracks squarely in place.

This machine can stand alone or be integrated into production lines. There are a variety of sizes and configurations available.

This model is an ideal solution for companies that manufacture light gauge steel wall panels. This includes off-site building manufacturers, modular builders, and panelized construction.

These panelized wall panel systems are more ergonomic than more common construction methods. With the ergonomic working height, the need to repeatedly kneel or hunch over to build panels has been eliminated. This makes the process safer for employees.

How it Works

The Light Gauge Steel Framing Station is composed of a steel framing table with a variety of features including squaring edges, squaring stops, foot-switches, pop-up rollers, push-button controls, stationary side, and a motor-driven telescoping side.

Tracks on the floor guide the telescoping side to set the panel height. Then, the C-channels and tracks are manually loaded onto the steel framing table. The user steps on a foot-switch that clamps the components against the squaring edge. This step guarantees the wall panel is square before being fastened.

Using the screw tool carriages, the C-channels are then fastened to the top and bottom tracks. After the light gauge steel wall is framed, it moves down the production line using raised pop-up conveyors. As an optional upgrade, power conveyors can move wall panels hands-free between stations.