Our production lines are designed to efficiently manufacture wall panels and floor cassettes from start to finish. A production line features an arrangement of products and accessories for continuous production flow. The layout of a production line is based on an organization’s production goals and the layout of their facility.

Whether you’re a startup plant, or you’re seasoned in the industry, Panels Plus offers a variety of production lines that are well-suited for those in the off-site, modular, and prefabricated building industries. In addition to the production lines we offer below, our team will also work with you to suggest a custom layout that best-suits your organization’s needs.

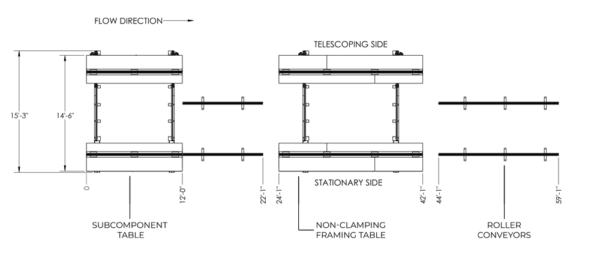

Interior Hand Framing Line

This is a non-clamping line and includes a Subcomponent Table and Roller Conveyors. The Interior Hand Framing Line is ideal for customers that want to manually fasten wall panels by hand. This line is also compatible with those using plate-marking saws.

Learn more here: Interior Hand Framing Line | Production Lines – Panels Plus (panplus.com)

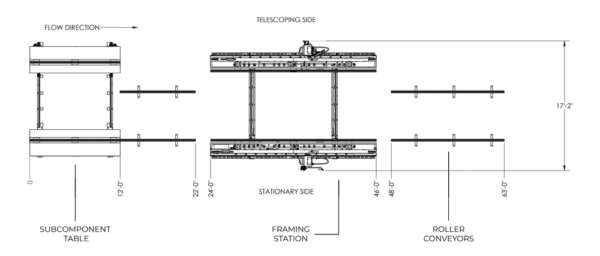

Interior Line

Designed for building interior wall panels, this system line is ideal for customers that want to run a line parallel to their exterior line to increase interior wall production capacity. With only one machine, the Interior Line is a great starting point for customers that are more budget-sensitive and want a system that can grow as their business grows.

Includes: Framing Station, Subcomponent Table(s), and Roller Conveyors

Learn more here: Interior Line | Production Lines for Panelized Building – Panels Plus (panplus.com)

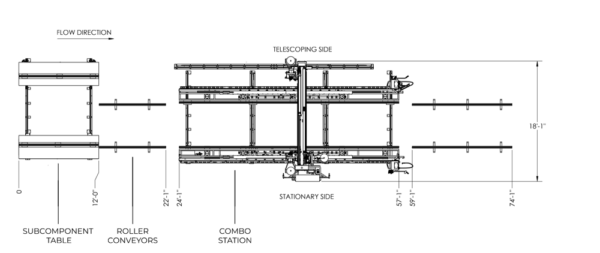

Combo Line

The Panels Plus Combo Line is an all-in-one system that frames and sheathes wall panels on one table. This system line has a small footprint. As it is a lower volume line, it is a great starting point for panelizing.

Includes: Combo Station, Subcomponent Table(s), and Roller Conveyors

Learn more here: Combo Line | Production Lines for Panelized Construction – Panels Plus (panplus.com)

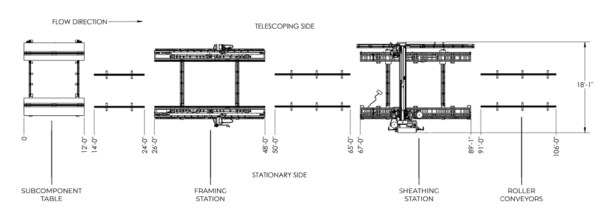

2-Table Line

The 2-Table Line frames and sheathes wall panels while maintaining a small footprint, perfect for those with limited space. This system is a great starting point for customers planning on adding more equipment as their business and budget grows.

Includes: Framing Station, Sheathing Station, Subcomponent Table(s), and Roller Conveyors

Learn more here: 2 Table Line | Production Lines for Panelized Builders – Panels Plus (panplus.com)

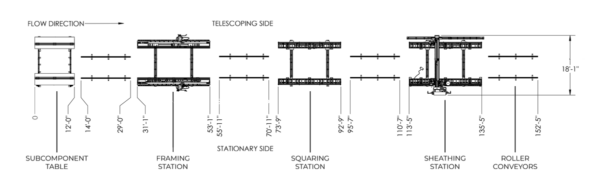

3-Table Line

The Panels Plus 3-Table Line is also known as a Full Production Line. It has the largest footprint and the highest production output in comparison to the other system lines. The 3-Table Line frames and sheathes wall panels.

Includes: Framing Station, Squaring Station, Sheathing Station, Subcomponent Table(s), and Roller Conveyors.

Learn more here: 3 Table Line | Production Lines for Panelized Builders – Panels Plus (panplus.com)

3-Table Router Line

The Panels Plus 3-Table Router Line is similar to the 3-Table line and includes a Squaring & Routing Station in place of a Squaring Station. This station incorporates a manual X-Y router bridge for routing out rough openings.

Includes: Framing Station, Squaring & Routing Station, Sheathing Station, Subcomponent Table(s), and Roller Conveyors.

Learn more here: 3-Table Router Line – Panels Plus (panplus.com)

You can read more about the production lines we offer and view full layouts on our website at: Production Lines | Panelizing Equipment – Panels Plus (panplus.com)